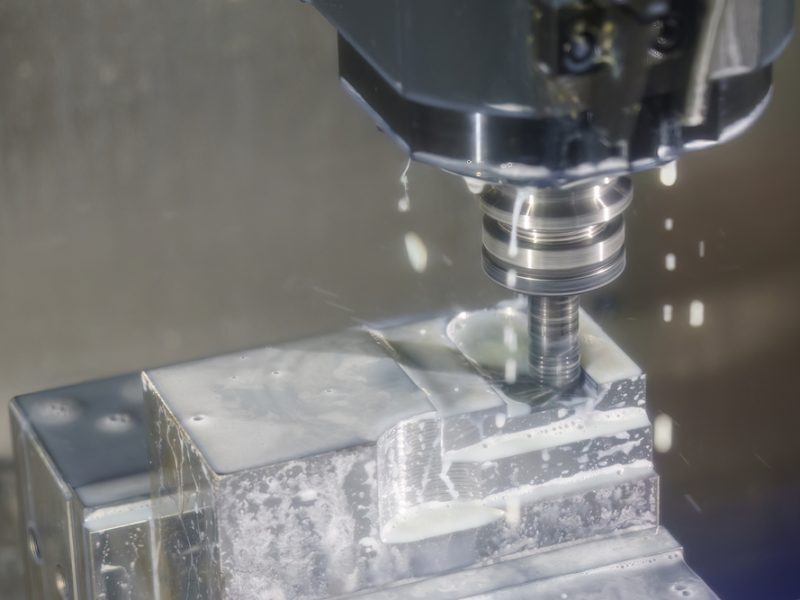

Get to Market Faster with High-Quality Metal Fabrication Services

You need parts that are accurate and consistent. And you need them fast. At KAL Manufacturing, our nimble team and state-of-the-art machinery deliver on all counts. When you partner with us, you get exclusive access to experienced engineers, designers, and craftsmen who are dedicated to your success. Our flexibility and responsiveness surrounding all our metal fabrication services ensure we can quickly meet your needs while maintaining quality. Learn more about our capabilities below, or reach out to our team with questions.

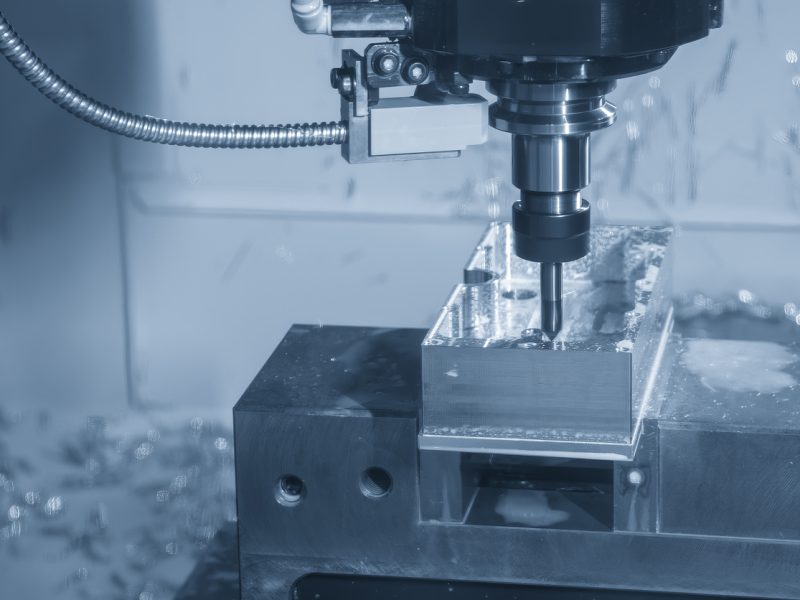

Get Metal Fabrication Services That Meet Your Needs

You need a team that understands your every need. Our size, agility, and experience allow us to get to know your business, creating the optimal solution for your goals. Partnering with us means tapping into 80+ years of experience with quality metal fabrication services. We’ll eliminate unnecessary steps, save you time, and reduce your costs.

You can be sure that you’re getting the highest-quality products possible when you work with KAL. We maintain a range of industry certifications to hold us to the highest standards in manufacturing excellence. We have ISO, UL, and ITAR accreditations, among others. With our experienced, certified team by your side, we’ll help skyrocket your business.