Quality Assurance

Proper quality assurance practices are crucial to the success of your project. That’s why we maintain a variety of certifications, including ISO, UL, and ITAR accreditations. Additionally, every stage of our manufacturing process features quality control measures to ensure that we create only quality parts, products, and assemblies.

Learn More

Engineering Support

With engineering support from some of our top engineers, you can maximize the potential of program design. We can eliminate manufacturability issues, ensure the highest level of quality, and help you realize the lowest possible cost.

Learn More

Supply Chain Management

The last thing you want is for your supply chain to slow you down. With our established, successful supply chain, we can mitigate any issues you may experience. If necessary, we can also collaborate with your existing supply chain to help integrate the entire process.

Early Supplier Involvement

With early supplier involvement, you know your project will be done right the first time. Our team will complement and enhance your internal capabilities, review for cost-saving strategies, and ensure quality. More importantly, we’ll set your project up for on-time delivery.

Program Management

A great program manager takes the stress out of the entire operation. After the initial stages of account development, we assign a program manager to be the single point of contact for the customer during the program lifecycle. This ensures efficient turnaround, seamless integration, continuous documentation, and real-time status updates.

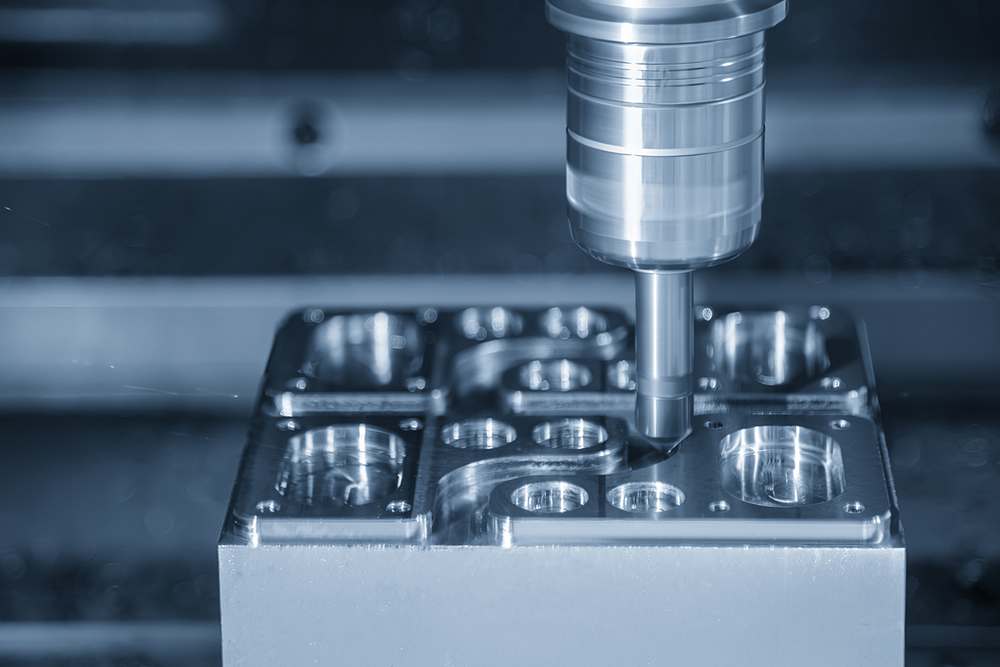

Partner with KAL Manufacturing for High-Quality Contract Manufacturing Services

Don’t entrust your contract manufacturing services to just anyone. At KAL Manufacturing, we take the time to get to know your business. Using that knowledge, we partner with your team to develop the right fit to meet your goals. When you choose KAL, you get 80+ years of proven success, the most experienced team, and access to exclusive state-of-the-art equipment. We’ll eliminate unnecessary steps, save you time, and reduce your costs.

Partnering with KAL Manufacturing means choosing a contract manufacturing services provider with quality in mind. We maintain a range of industry certifications to hold us to the highest standards in manufacturing excellence. We have ISO, UL, and ITAR accreditations, among others. These certifications, combined with our quality assurance processes, mean you don’t have to worry about quality issues.