The metal fabrication process is crucial to a wide range of industries, from construction to automotive manufacturing, and more. Understanding this process more fully can give you tools to make better-informed decisions for your business. In this blog, we’re diving into each step of the metal fabrication process from design to the final assembly. Let’s get started.

Design and Engineering

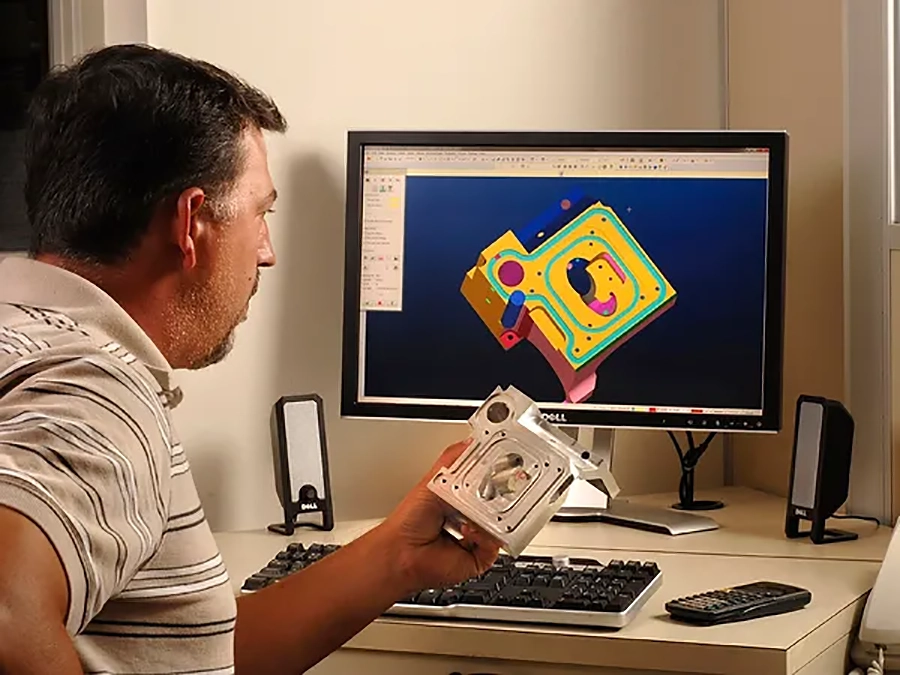

The metal fabrication process begins with designing and engineering the product. During this phase, you’ll work with engineers to determine factors such as strength requirements, tolerances, and cost considerations. Your team will work with a computer-aided design (CAD) program to create a detailed blueprint of the final product. This involves defining exact measurements, material types, and more.

When going through this process, there are a few things you’ll want to keep in mind. An example is your material selection. Different materials will have unique properties like strength, corrosion resistance, and more. An experienced manufacturer can help you find what’s right for you. Additionally, they can help you identify any other unique factors you’ll have to consider for the final product.

Prototyping

Once the design is finalized, engineers and designers can create physical models of their ideas for testing and evaluation. The most common method for metal prototyping is CNC machining. It offers precision, versatility, and quick turnaround times. Additionally, it’s ideal for creating parts with tight tolerances and complex geometries.

However, CNC machining isn’t the only process engineers and designers use. Sheet metal prototyping may be used for things like enclosures, panels, and other parts that require bending and forming of metal.

Fabrication

Next, it’s time to actually create the product. The first part of this process involves cutting and shaping the components. Common methods may include laser cutting, waterjet cutting, or plasma cutting. Shearing and sawing are also commonly used.

Some components may also need CNC machining to achieve tight tolerances and smooth surfaces. Others may move into a welding and joining stage right away. Your chosen partner will be able to outline the exact stages of your specific process during the design phase.

Surface Finishing

After the components are joined, the metal might have rough edges, weld marks, or oxidation that must be removed. That’s where surface finishing comes into play. These processes improve the appearance, functionality, and durability of the product. It may include grinding, polishing, blasting, or powder coating the components.

Inspection and Quality Control

Once the fabrication process is complete, your partner will ensure the product meets the required specifications and quality standards. This could involve a range of inspection techniques, from visual inspections to advanced non-destructive testing methods. Of course, it will depend on your specific project.

Work with KAL Manufacturing for Your Metal Fabrication Needs

If you’re looking for a quality metal fabrication process, turn to the KAL Manufacturing team. Since 1943, we’ve been dedicated to crafting high-quality custom-machined parts. We have a variety of extensive capabilities, such as CNC machining, sheet metal fabrication, electro-mechanical assembly, and prototyping. Additionally, we maintain ISO, ITAR, and UL accreditations to hold us to the highest standards of manufacturing excellence. We have experience helping OEMs and Fortune 500 companies create custom-machined parts that exceed expectations, and we’re ready to help you with your next project.

Our shop has advanced machinery that can achieve tolerances down to 0.003-0.005 inches. We’re equipped with 20,000 RPM dual pallet, high-speed machining centers with fourth-axis capabilities and vertical machining centers. This extensive machinery allows us to build tooling in-house and take on projects of all volumes and material types. Whether your part must be made of aluminum, steel, stainless steel, or plastic, we can help.

Let’s Get Started

Want to learn more about what we can do for you? Contact our expert team today to get started.